MANUFACTURING

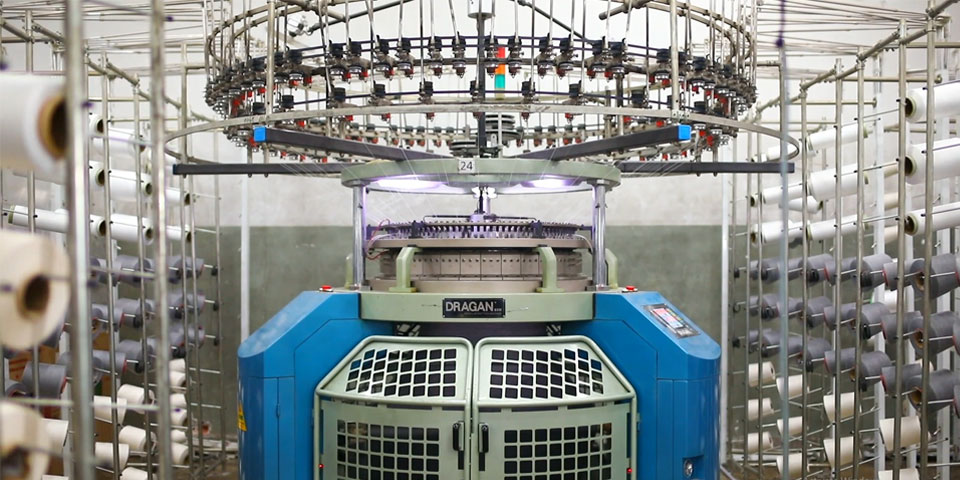

KNITTING

Our most modern Knitting Facility has supported us to build this Knit Apparels Business. Our Knitting facility contains assorted variety of special fabric construction.

DYEING

Dyeing facility is the backbone of “Kay & Emms” enabling marketing activities fruitful by delivering top class Fabrics to the Garments Division. The dyeing stuff of Kay & Emms always conforms to the required standards of each customer like OEKOTEX, REACH, and many others.

CUTTING

Cutting department is equipped with state-of-the-art auto-cutting machines having the capacity to cut 12000-15000 pcs per day, while the manual-cutting output is 7000-10000 pcs per day, sufficient enough to fulfill the required need of stitching units.

EMBROIDERY

Embroidery department at Kay & Emms is equipped with Japanese computerized embroidery machines from BARUDAN supported by 20 multi-head,

STITCHING

With over 600 stitching machines, manned with the most skilled and expert operators, Kay & Emms is capable of producing versatile garments ranging from basic to high fashion covering Men’s, Women’s & Kid’s categories with maximum flexibility in size and color assortments.

FINISHING

Fabric Finishing department at Kay and Emms is comprised of automated Stenter, Continuous Tumbler, Raising, Sweeding and state of the art Compactor Machines to give the best quality finishes as per international standards. The department is providing distinctive category of finishing effects through resin application, flame retardant, water repellent and anti- microbial finishes.

LAUNDRY

Garment Wet Process Department is proficient enough to give several categories of washes with support of “TUPESA RANGE” Burnout, Pigment Dyeing, Oil Wash/ Cold Dyes, Dip Dye Tie ,Acid Dye, Wash Spray ,Wash Sand , Leather Coating and Chemical Brushing havingproduction capacity of 2,40,000 Pcs per month.

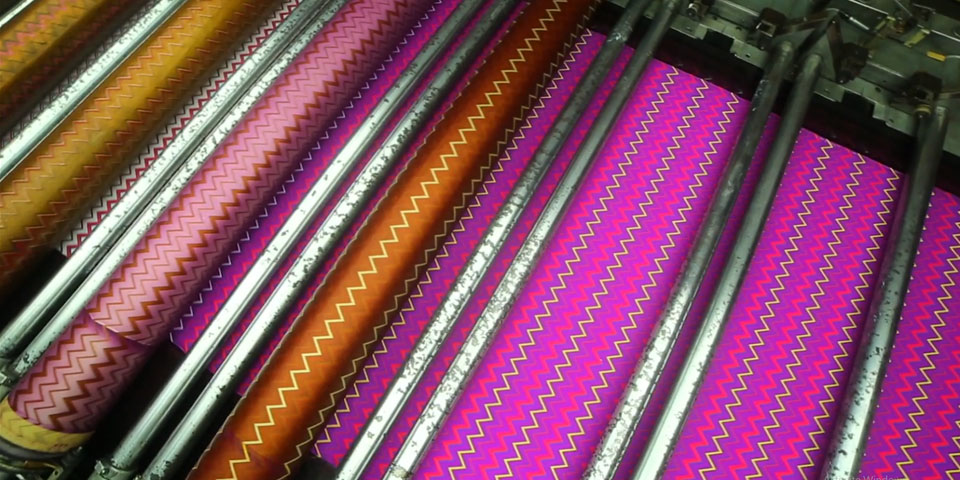

ROTARY PRINTING

The company is capable to print all types of knit fabrics covering 08 colors with a Repeat Size of 640MM & 914MM. At Kay & Emms our highly skilled and talented staff runs full service Research & Design center. We can also duplicate customer’s design samples upon customer’s requirement.